首页产品中心

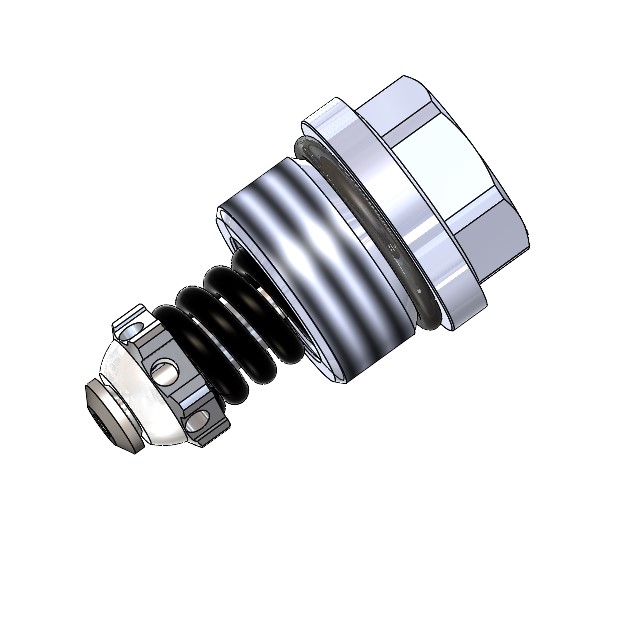

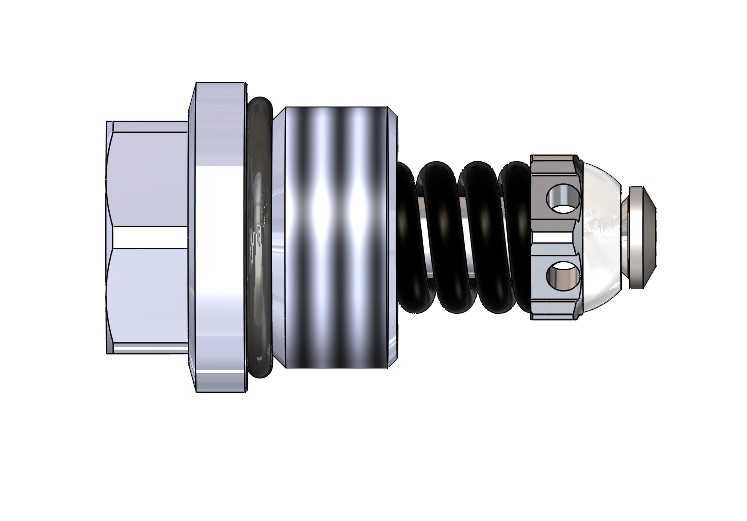

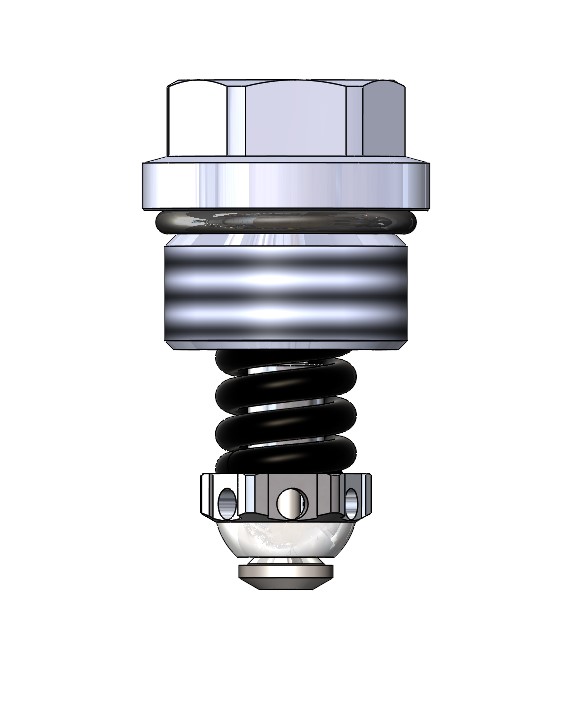

溢流阀DRV0M-27系列

产品优势

锥阀经过热处理硬化并经过精密加工,保证更低的內泄漏及更长的使用寿命。外部零件外表面都是经过镀锌处理和防腐蚀处理。所有零部件均采用高强度钢材制造。结构紧凑、体积小。压力由生产工厂设定,出厂后不可调节。可选的弹簧压力范围最大至 400bar。

Poppet is hardened and ground to guarantee minimal wear and to extend service life. All external surfaces are zinc plated and corrosion-proof. All valve parts are made of high strength steel. Compact size. Pressure setting is pre-adjusted by the factory and cannot be changed. Optional spring ranges to 400 bar .

详细参数

| 最大工作压力 Maximum operating pressure | 400 bar |

| 最大流量 Maximum flow | 150 l/min |

| 设定压力 Setting pressure | 查看订货选型表 See table in Ordering code |

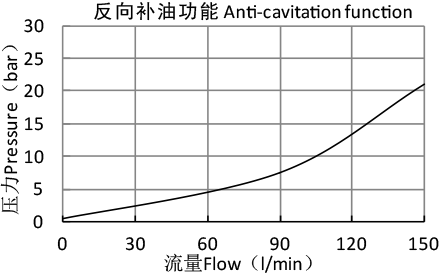

| 单向阀开启压力 Anti-cav cracking pressure | <0.5bar |

| 最大内泄漏量 Maximum internalleakage | 3cc /min @ 80%设定压力 3cc /min @ 80% nominal set point |

| 外露零件表面处理要求 External component treatment | Zn/Fe - standard Zn/Ni |

| O型圈温度范围 O-ring Temperature Range | -30°C to 110°C(标准密封NBR-BUNA-N) |

| 适用油温范围 Oil Temperature Range | -30°C to 110°C |

| 达到设定压力时的流量 Pressure settings established | 10 l/min |

| 适用工作介质 Fluids | 矿物油或具有润滑性的合成油液 Mineral - based or synthetics with lubricatin gproperties |

| 工作个质粘度范围 Viscosities | 7.4 to 420 cSt |

| 过滤要求 Filtration | 20/18/15 ISO 4406 (maximum filtration admitted) |

| 安装方向 Orientation | 无限制 No restrictions |

| 安装力矩Installation torque | 70-80 Nm (Hex.24) |

| 密封件代号 Seal kit code | SK.058 |

| 测试条件 Technical specifications for characterization | 见尾页1-2 see the last page 1-2 |

| 测试液压油型号 Oiltesting condition | ISO VG 46 cSt |

| 重量 Weight | 0.14kg |

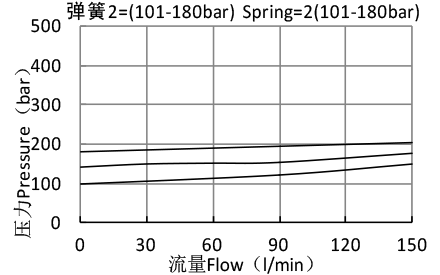

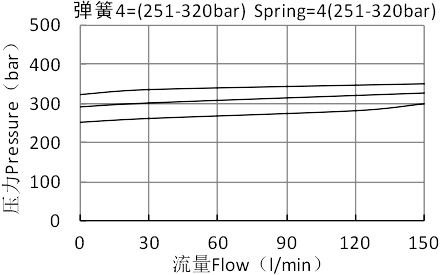

特性曲线

注意: 特性曲线图显示出了弹簧的每个偏差选择的流量处理能力。在油温为 40C和粘度 为 46 cst时记录了 p/Q 曲线。

NOTE: The performance chart illustrates flow handling capacity for each spring bias options. p/0 curvesare recorded at TOil = 40° C and 46 cSt

订货编号

1688

1688 搜索

搜索