TJX series

High-efficiency machining centrifuge

*TJX series is a spindle moving type-walking machine introduced by DESUN Company, which is an efficient machining machine tool developed mainly for processing small parts, mainly for processing slender shaft workpieces. The introduction of this machine tool fills the solution that DESUN Company does not have long shaft products.

*TJX centripetal machine faces the market and mainly faces the customer segmentation of slender shaft processing. TJX centripetal machine emphasizes the high rigidity and high precision turn-milling compound machining of machine tools. In order to solve the problem of insufficient rigidity in the past, TJX series has been praised by many customers for its high stability processing.

*TJX series is our positioning mid-range mass production machine tool, with flexible configuration suitable for enterprises of different scales and industries, focusing on the processing of long-axis small parts, and improving efficiency by using bar machine for on-line processing. TJX is a brand-new innovative design scheme with two spindles and a turret +Y axis. No matter high-efficiency machining or heavy cutting, TJX can handle it freely!

*Ensure the highest rigidity of the machine tool, including the best dynamic response and high-strength base shock absorption. At the same time, it will also prolong the tool life, improve the surface smoothness of parts, and reduce the workpiece beat and processing time.

TJX series centrifuges have rich configurations, and the specific models are as follows:

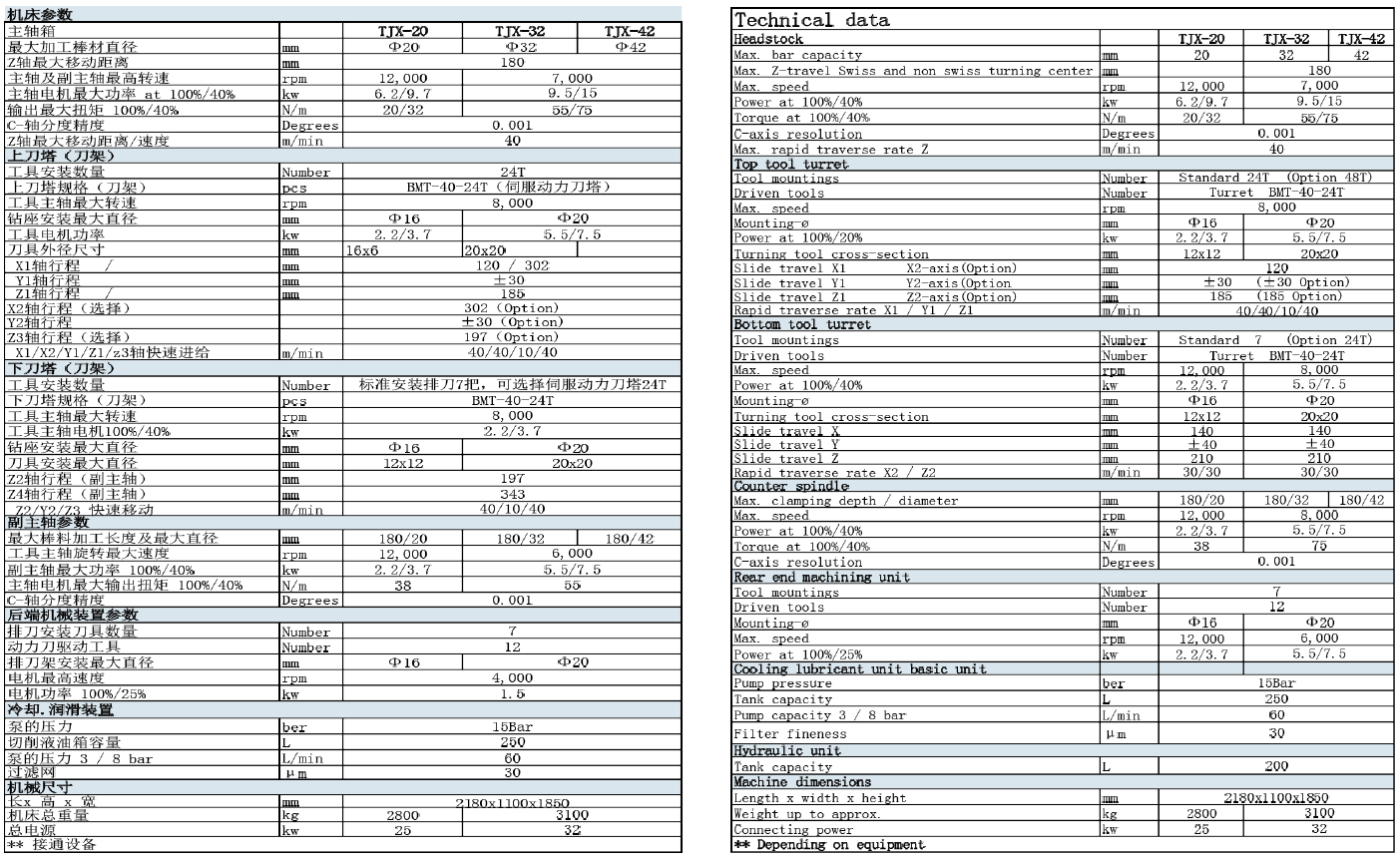

- TJX-20 series small turning compound center

- TJX-32 type centripetal machine series medium-sized turning compound center

- TJX-42 type centripetal machine series medium-sized turning compound center

Machine Tool Design Concept and Optional Accessories (Option)

*TJX series is a model of centrifuges under Seiki, covering 100% of the market demand for centrifuges.

*Bar diameter, standard configuration between Φ20mm/Φ30mm/Φ42mm, depending on the spindle size.

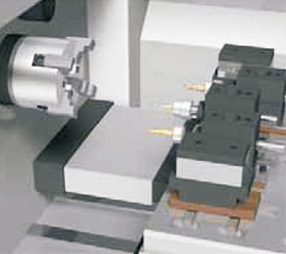

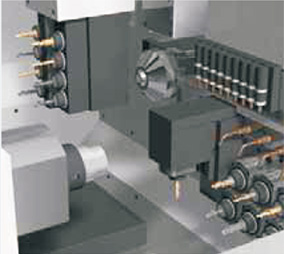

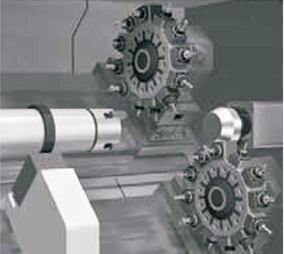

*TJX-20/32/42 series adopts BMT-40-24T servo power turret, and a single turret can install 24 different cutters.

*Choose to use double servo power turret, two turret can install up to 60 knives.

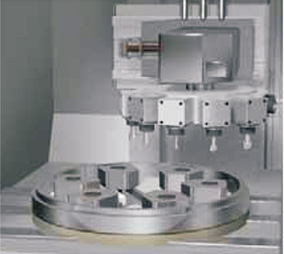

*High-quality, high-efficiency back machining, reducing the loss of workpiece precision caused by repeated clamping.

*High-speed movement, TJX-20/30/42 moves 45 meters quickly

*The standard configuration functions of TJX are simultaneous rotation and docking of double spindles, rapid rotation and positioning of double C axes and high rigidity milling.

Introduction of functions and advantages of TJX series centrifuges

*The machine tool adopts double spindles, double C-axes, single turret and single Y-axis, which is powerful and has excellent performance. The machine tool is extremely powerful.

*Because the machine tool has good stability and rigidity, the tool life is long, for example, the tool life is increased to 38% compared with the earlier machine tool.

* The diameter of the X-axis lead screw reaches 32 mm. Under long-term high-speed operation, the large-diameter lead screw can effectively guarantee the precision and service life of the machine tool for a long time.

*Adopt P-class 30mm roller guide rail to ensure the long-term high-efficiency heavy cutting task of the machine tool

*TJX full range machine tools are driven by motorized spindle, with fast response, low failure rate and easy maintenance.

*Standard configuration of 15Bar high-pressure system ensures that the machine tool can easily deal with deep holes

*Automatic material receiving hand configuration, so that after the processing task is completed, it is automatically taken out by the material receiving hand and placed in the finished product box, which is truly unmanned processing.

Machine tool design

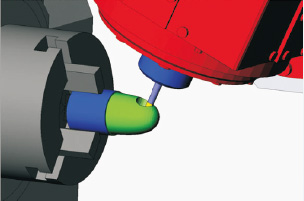

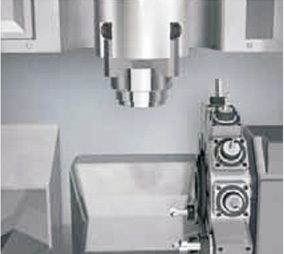

TJX series is analyzed by advanced finite element technology. After repeated verification, it achieves high rigidity and lightweight fuselage. This model adopts all roller guides. Compared with the traditional ball guides, the roller guides have the excellent characteristics of smaller elasticity relative to the load. By assembling a large number of roller bodies in the sliding unit, the rigidity can be several times higher than that of the ball guides. Orthogonal Y-axis, using its straight-forward characteristics and high-speed feed, can realize efficient machining, and using the structure with excellent rigidity, can realize the same or even higher machining accuracy as the machining center. As a new type of compound processing machine beyond the scope of turn-milling compound center, it has excellent turn-milling processing ability.

Machine tool design considerations

The high rigidity of the machine tool is the key to determine the later application accuracy of this machine tool. German engineers first consider the application of cast iron when developing the machine tool. The internal structure design of cast iron ensures that the machine tool is not easy to be thermally deformed in the later high-speed machining, and the vibration of the machine tool is also the main reason that affects the product size. In the research and development, engineers fully consider the later application scenarios of the machine tool and try to summarize and pay attention to the unfavorable factors. The excellent performance of TJX series machine tools with high precision and high stability perfectly reflects the German engineers.

Cold and heat machine solution

TJX series adopts rod materials of 20mm and 32mm, and all electric spindles are realized. The spindle is cooled by special spindle oil at constant temperature, which ensures that the spindle body is fully cooled during high-speed rotation, and the thermal elongation is effectively controlled. The cutting fluid temperature is also our concern, because the continuous rise of cutting fluid temperature will also affect one of the main reasons for the change of workpiece size and quality, and the heat of cooling fluid can be effectively discharged and improved. Only in this way can we achieve continuous and stable high-precision machining. TJX series can manage the cooling of spindle and cutting fluid at the same time, effectively narrow and reduce the space temperature gap between machine tools and factories, shorten the change time of cold and hot machines, improve the qualified rate of products, and achieve the goal of producing high-quality workpieces.

Intelligent cooling system

*Electrical cabinet air conditioning, TJX standard full range of electrical cabinet air conditioning, to ensure that electrical appliances and drivers work stably in a constant temperature environment for a long time.

* Cutting fluid air conditioner, TJX series full range standard configuration cutting fluid air conditioner, aimed at cutting fluid constant temperature, so that workpiece processing will not change because of cutting fluid temperature change (Option).

*Electric spindle oil-cooled air conditioner, TJX series full series standard configuration spindle oil-cooled air conditioner, to ensure that the spindle works for a long time, the spindle temperature is kept in a reasonable state, and the spindle precision is improved.

* The hydraulic station is equipped with oil suction (oil outlet) filter and oil return filter as standard. When the machine tool runs for too long, hydraulic oil is circulating, and hydraulic oil is mixed with scrap iron because of normal wear of the machine, the pump of the hydraulic station is well protected by the filter.

* The hydraulic oil pipe is upgraded from the original rubber pipe to galvanized steel pipe to ensure that the oil pipe will not age after many years of machine tools.

* 40Bar high-pressure system can be configured to ensure that the machine tool can easily deal with (Option) when processing deep holes.

Simulation and verification

ESPRIT intelligent programming solution, ESPRIT-CAM software enables you to simulate tool processing on a machine tool through a 1:1 machine tool model in a computer through ESPRIT software before cutting, so as to find tool interference in advance, take measures to avoid machine collision due to tool interference, and reduce the loss caused by maintenance and shutdown of enterprises due to carelessness or ignorance of machine tool performance. ESPRIT software can solve the problem of easy to learn, intelligent generation of machining tool path and quickly calculate complex tool path, reducing errors. Users only need one system to complete the programming of turning-milling compound machining. The operation interface of the software is friendly and easy to learn. Interference prevention simulation function. Machine tool collision prevention function. Comprehensive man-machine dialogue function and intelligent programming.

We recommend to choose a set of such software, which is very necessary for programming multi-axis compound machine tools in production! For the huge loss caused by programming efficiency and programming misoperation, a set of software is worth investing!

Nidec Co.,LTD MP ruler is a strategic partner of DESUN Company, and DESUN Company configures MP synchronous ruler (grating ruler) in the X-axis standard of all its products.

From a highly integrated operating system, it is convenient for customers to useThe whole series adopts Japanese Mitsubishi high-end series -M80Focus on production and control-including future industry 4.0

*High-speed, high-precision contour control function;

*Hydraulic turning, rigid tapping, hydraulic milling and hexagonal turning functions;

*Virtual and development functions, plane collision prevention, real-time mode;

*Tool R angle compensation function, tool wear compensation function;

*Spindle-vice spindle C axis synchronization detection, rotation synchronization detection, docking synchronization detection;

* Multi-channel (3) independent processing function;

*Taper circular processing, non-circular processing function;

*Chamfering and R-angle turning function;

*Internet wireless link remote diagnosis function.

Strengthen lathe function

The functions of milling and multi-axis and multi-system control are greatly strengthened.

In addition, it also improves the on-site maneuverability and can carry out more complex processing simply and efficiently.

Turning machine

Automatic lathe

Vertical lathe

Inverted lathe

Compound processing machine

More complicated processing can be performed simply and efficiently.

It is equipped with rich functions to support high productivity. By supporting high-speed and high-precision control and SSS control, the milling function is enhanced and the multi-axis and multi-system control function is enriched. In addition, it has greatly improved the functions frequently used by field personnel, such as tool correction and workpiece coordinate system compensation, greatly improved the usability of programming, and can easily carry out various more complicated machining.

Milling function

High speed and high precision control /SSS control

Servo spindle motor control

Functions for Large Lathe

Re-tapping and spindle ratio

Real-time adjustment

Large display

Programming of dialogue mode

Multi-system waiting program editing

Dialog mode insertion loop instruction

3D program checking

Multi-axis multi-system control function

Maximum support: 8 systems, 32 axes and 8 spindles.

Loader control with subsystem control

Spindle overlap, multi-spindle synchronization

On-site handling

Workpiece coordinate system compensation

Can simply set the restricted area inspection parameters.

Can switch to a condensed picture

Parameter introduction

1688

1688 Search

Search