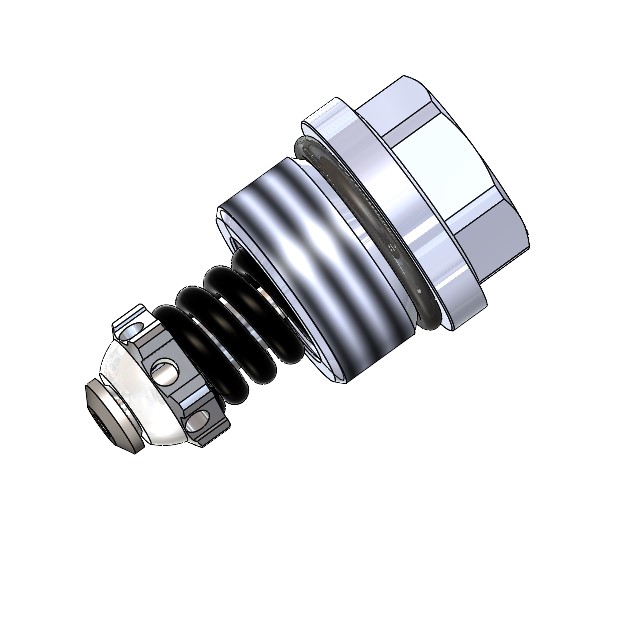

DRV0M-27

-

Relief Valves

-

DRV0M-27

-

-

150L/min

-

400bar

-

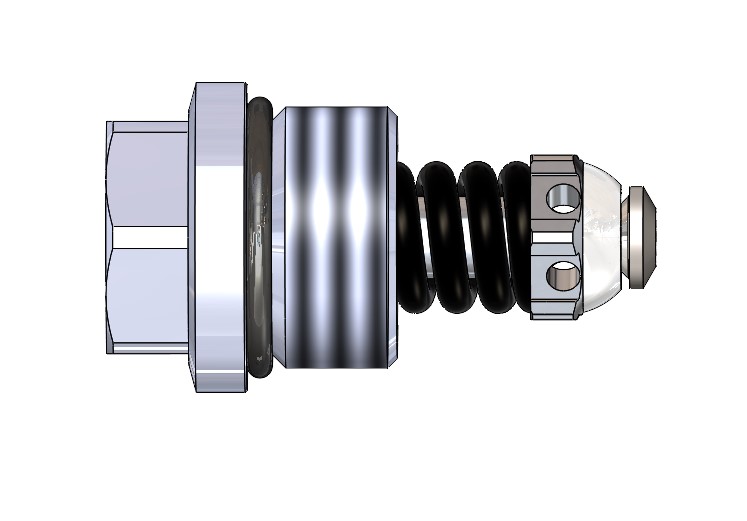

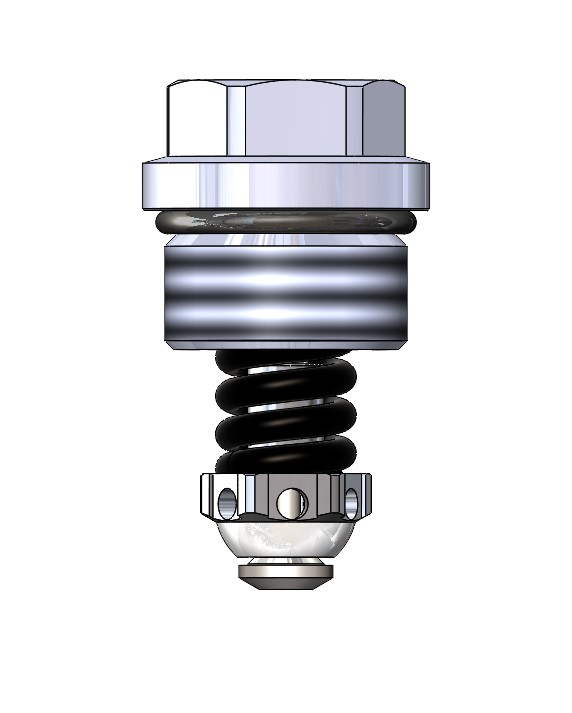

该阀在紧凑式螺纹插装阀结合了减震阀和通过止回阀实现补油的典型功能。在压力下的泄压功能,它是通过一个侧入式鼻排气阀完成的,由于智能导流板设计实现非常低的压力上升。当压力在高压端口(1) 达到阀门设定,阀门启动打开通往油箱端口(2)。在自由反向液流中 一个非常轻的偏置弹簧允许液流易于从鼻端流通到侧端(2 到1)高精度加工保证快速响应负载变化,有限迟滞和减少内部和外部泄漏。 The valve combines in one compact insert cartridge the typical function of shock relief valve and anti-cavitation through the check valve. In the pressure relief function it’s a side-in nose-exhaust valve, with very low pressure rise thanks to the smart deflector design. When the pressure at the high pressure inlet(1) reaches the valve setting, the valve starts to open to tank (2). In the free reverse flow function a very light bias spring allows for ease of flow passage from nose to side (2 to 1). High precision machining guarantees quick response to load changes, limited hysteresis and reduced internal and external leakage.

Product Advantages

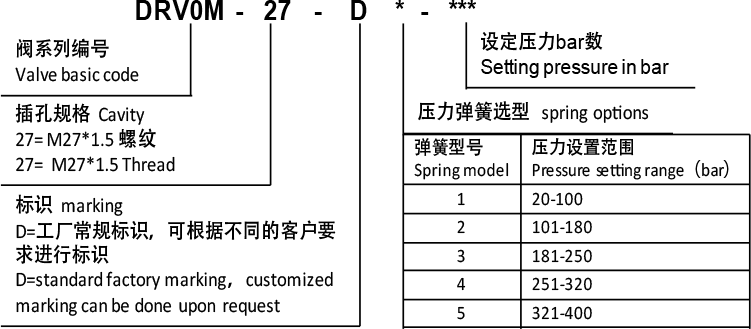

锥阀经过热处理硬化并经过精密加工,保证更低的內泄漏及更长的使用寿命。外部零件外表面都是经过镀锌处理和防腐蚀处理。所有零部件均采用高强度钢材制造。结构紧凑、体积小。压力由生产工厂设定,出厂后不可调节。可选的弹簧压力范围最大至 400bar。

Poppet is hardened and ground to guarantee minimal wear and to extend service life. All external surfaces are zinc plated and corrosion-proof. All valve parts are made of high strength steel. Compact size. Pressure setting is pre-adjusted by the factory and cannot be changed. Optional spring ranges to 400 bar .

Detailed parameters

| 最大工作压力 Maximum operating pressure | 400 bar |

| 最大流量 Maximum flow | 150 l/min |

| 设定压力 Setting pressure | 查看订货选型表 See table in Ordering code |

| 单向阀开启压力 Anti-cav cracking pressure | <0.5bar |

| 最大内泄漏量 Maximum internalleakage | 3cc /min @ 80%设定压力 3cc /min @ 80% nominal set point |

| 外露零件表面处理要求 External component treatment | Zn/Fe - standard Zn/Ni |

| O型圈温度范围 O-ring Temperature Range | -30°C to 110°C(标准密封NBR-BUNA-N) |

| 适用油温范围 Oil Temperature Range | -30°C to 110°C |

| 达到设定压力时的流量 Pressure settings established | 10 l/min |

| 适用工作介质 Fluids | 矿物油或具有润滑性的合成油液 Mineral - based or synthetics with lubricatin gproperties |

| 工作个质粘度范围 Viscosities | 7.4 to 420 cSt |

| 过滤要求 Filtration | 20/18/15 ISO 4406 (maximum filtration admitted) |

| 安装方向 Orientation | 无限制 No restrictions |

| 安装力矩Installation torque | 70-80 Nm (Hex.24) |

| 密封件代号 Seal kit code | SK.058 |

| 测试条件 Technical specifications for characterization | 见尾页1-2 see the last page 1-2 |

| 测试液压油型号 Oiltesting condition | ISO VG 46 cSt |

| 重量 Weight | 0.14kg |

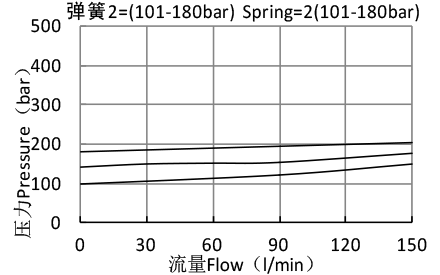

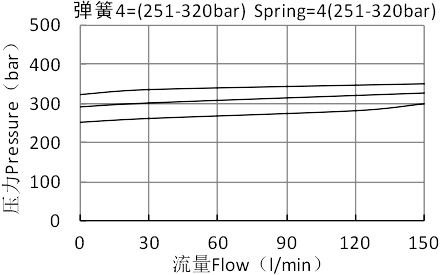

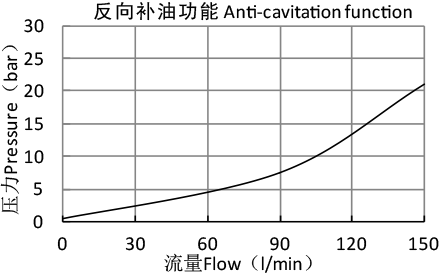

Characteristic Curve

注意: 特性曲线图显示出了弹簧的每个偏差选择的流量处理能力。在油温为 40C和粘度 为 46 cst时记录了 p/Q 曲线。

NOTE: The performance chart illustrates flow handling capacity for each spring bias options. p/0 curvesare recorded at TOil = 40° C and 46 cSt

Ordering Code

1688

1688 Search

Search