In this case, a high-speed flexible gripping unit combined with a vibrating disk and a self-developed mechanical arm is used, and intelligent AI detection equipment and system are used to accurately distinguish qualified products from defective products. Intelligent sorting unit classifies them according to the detection results, and analyzes the production status according to the statistical results.

Case introduction of automation integrated solution

Flexible global dimension high precision AI detection case

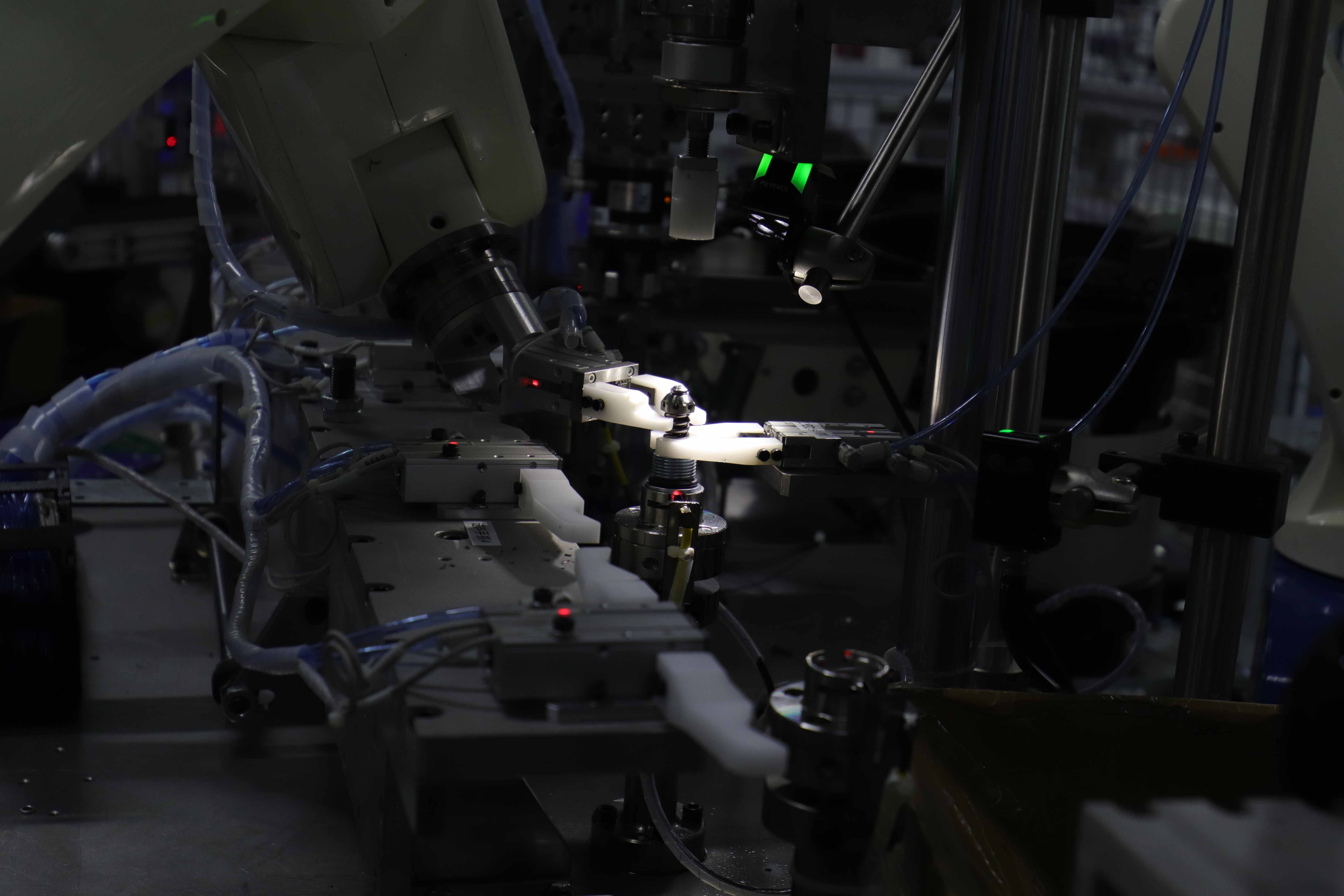

Flexible global dimension high precision AI detection case Multi-directional intelligent high-precision detection case

Multi-directional intelligent high-precision detection caseIn this case, a self-developed flexible transmission unit and a composite detection unit are used to accurately measure the parameters of parts in multiple directions, the intelligent sorting unit classifies products according to the detection results, and the production status is monitored in real time in the background of the Internet of Things.

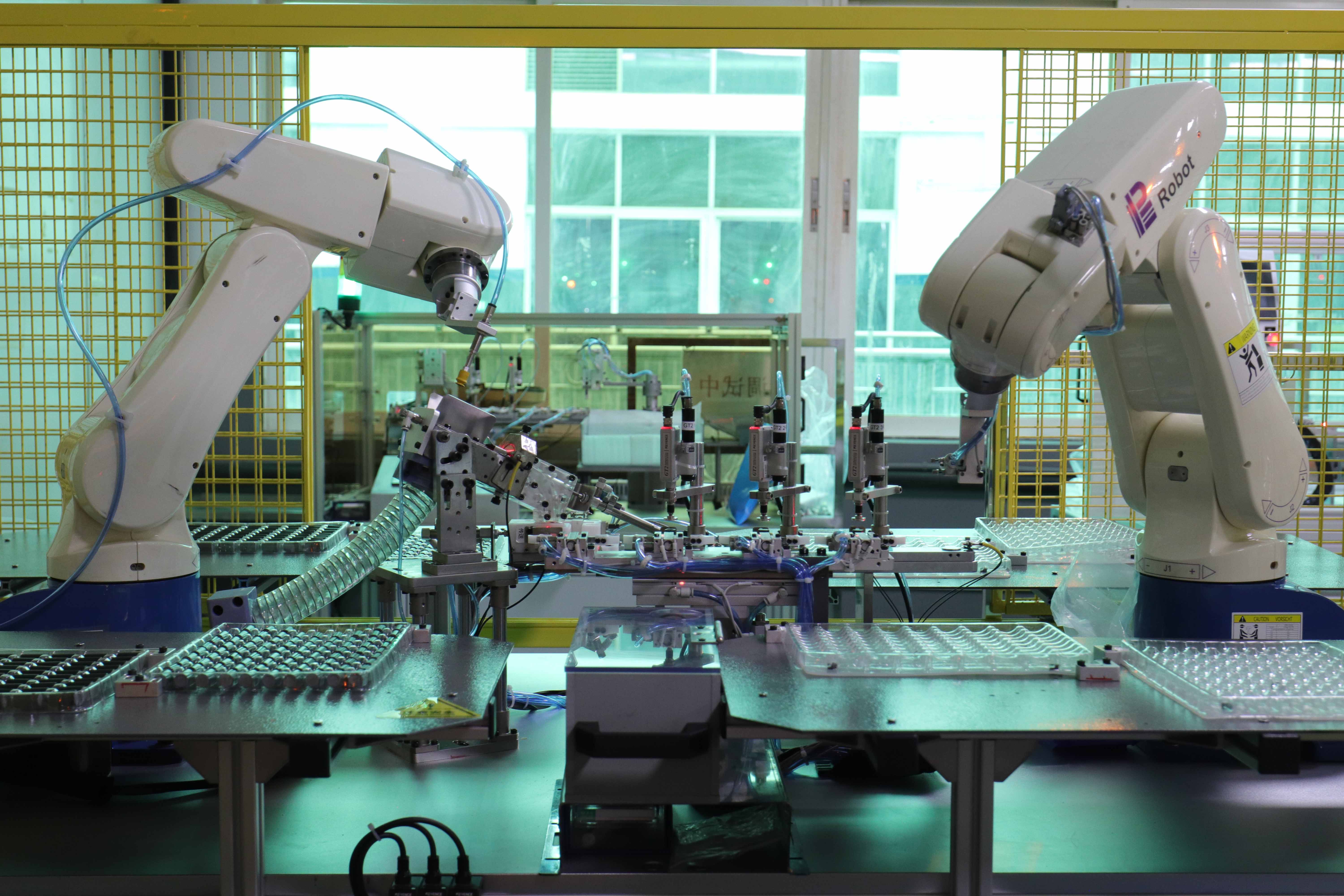

Flexible assembly case of complex parts

Flexible assembly case of complex partsIn this case, a variety of assembly processes are designed, so a flexible assembly unit is formed by multi-machine linkage, and high-precision visual AI is used to detect equipment, monitor assembly situation, close-loop tracking of parts information, and real-time visual remote monitoring of production status.

Intelligent and high-precision AI inspection case of contaminated parts

Intelligent and high-precision AI inspection case of contaminated partsIn this case, the intelligent visual guidance system is used to pick up the contaminated parts with liquid foreign bodies such as oil and water, and the detection unit intelligently filters the influence of impurities, and intelligent sorting is completed after accurate detection.

1688

1688 Search

Search